Top 5 Mistakes to Avoid While Using a Mould Polishing Machine

When it comes to die and mold making, polishing is not just a finishing act; it is a vital quality control step. The better the polishing of a mold, the better the output, lesser the defects, and longer will be the life of the tool. But with whichever mold polishing machine in the world, if the machine operator or technician does not know the correct technique or usage, it can wipe off the benefits.

To enable the toolroom folks to maximize output, let's look at the 5 common mistakes to avoid while using a mold polishing machine and how the choice of the right brand like Plassteze matters.

Why Mould Polishing Matters

- Improves surface finish of plastic and metal parts

- Reduces defects such as flow lines, burrs, or rough edges

- Boosts mould lifespan by reducing friction and wear

- Prevents part sticking for easier ejection

- Supports faster cycle times in production

But if not done properly, polishing can damage the mould instead of enhancing it.

Top 5 Mistakes to Avoid While Using a Mould Polishing Machine

1. Using the Wrong Polishing Tools or Compounds

Not all materials require the same polishing approach. Using abrasive stones or compounds not suited for the mould material can cause scratches, warping, or dimensional loss.

Tip: Use the correct grit size, compound, and tool for each material. Plassteze’s mould polishing equipment supports a wide range of tool attachments for all types of surface finishes.

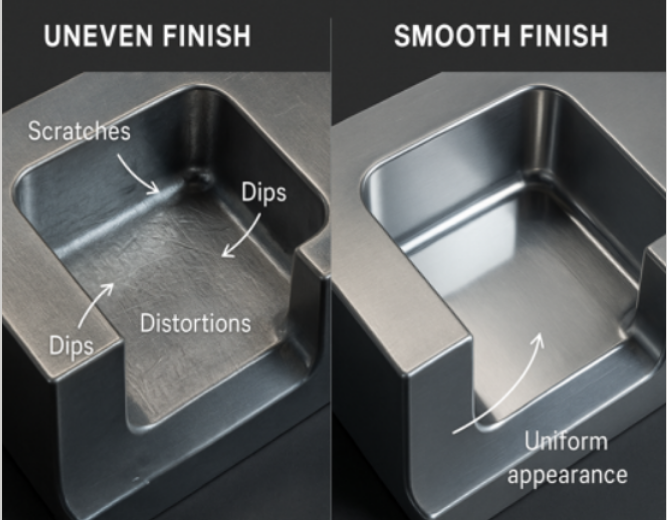

2. Applying Uneven Pressure

Applying too much or inconsistent pressure while polishing can cause dips, distortions, or uneven finishes.

Tip: Maintain even, circular motions and let the machine do the work. Plassteze’s ergonomic, low-vibration machines allow precise control for consistent pressure.

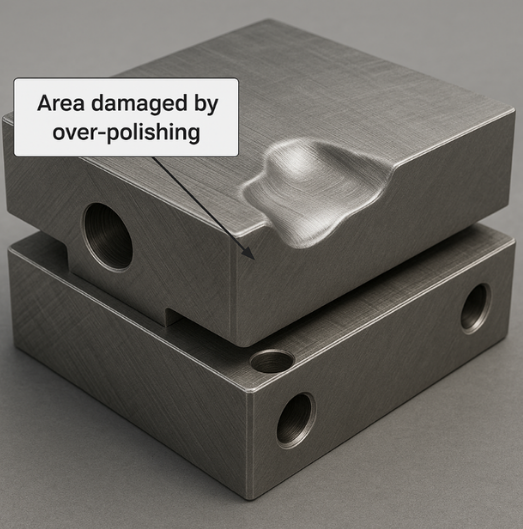

3. Over-Polishing the Surface

Excessive polishing, especially in tight corners or fine details, can remove essential material or alter dimensions.

Tip: Know when to stop. Always follow a progressive grit approach and inspect between stages. Plassteze machines offer adjustable speed settings for safe and precise polishing.

4. Ignoring Safety Measures

Operating without proper PPE or not securing the mould properly can lead to accidents.

Tip: Follow all safety protocols. Plassteze machines include insulated handpieces and smooth controls for safe use.

5. Neglecting Machine Maintenance

Neglecting care can lead to downtime, poor results, or early failure.

Tip: Clean and inspect your machine regularly. Replace accessories and check speed controls. Plassteze machines are low-maintenance and built for daily use.

Why Trust Plassteze for Mould Polishing Equipment?

- Versatile tool compatibility

- Adjustable speed controls

- Compact, ergonomic design

- Reliable support and spare parts availability

- Ideal for both small mould shops and large industrial units

Whether you're polishing plastic injection moulds, metal dies, or medical-grade tooling, Plassteze has the perfect solution to meet your standards.

Conclusion

A mould polishing machine is a powerful tool, but it needs the right approach. Avoiding these five common mistakes will help you achieve better surface finishes, fewer defects, and longer mould life.

And with Plassteze, you’re not just buying a machine — you’re investing in precision, reliability, and results.

Upgrade your polishing process with Plassteze – the trusted name in die & mould solutions.

Frequently Asked Questions (FAQs)

- Can over-polishing damage a mould permanently?

Yes. Over-polishing can remove critical surface layers or alter fine details, leading to poor part quality or even mould rejection. - What is the recommended polishing frequency?

It depends on usage. High-volume moulds may need light polishing after every production cycle, while others may need it less frequently. Regular inspection is key. - How do I know which polishing tool to use?

Start with coarser tools for rough surfaces and move to finer grits for finishing. Plassteze provides tool recommendations based on mould type and finish goals. - Is machine maintenance really necessary if it works

fine?

Yes. Even if it seems fine, neglecting maintenance leads to wear, inefficiency, or sudden breakdowns. Regular checks extend the machine’s lifespan. - Why is Plassteze preferred by toolrooms?

Plassteze offers industry-trusted solutions with advanced features, reliable performance, and expert support — making it the go-to choice for polishing and mould equipment.