Why Every Toolroom Needs a Mould Polishing Machine?

In the fast-paced world of mould manufacturing, every detail matters. A flawless surface finish not only improves product quality but also extends mould life, reduces defects, and enhances productivity. That’s where a mould polishing machine becomes an essential asset.

Whether you're in plastic injection moulding, die casting, or precision tooling, polishing is the final step that ensures your moulds are truly production-ready.

At the forefront of precision tooling solutions, Plassteze stands out as a trusted name in die & mould solutions, offering high-performance mould polishing equipment designed to meet modern toolroom demands.

What is a Mould Polishing Machine?

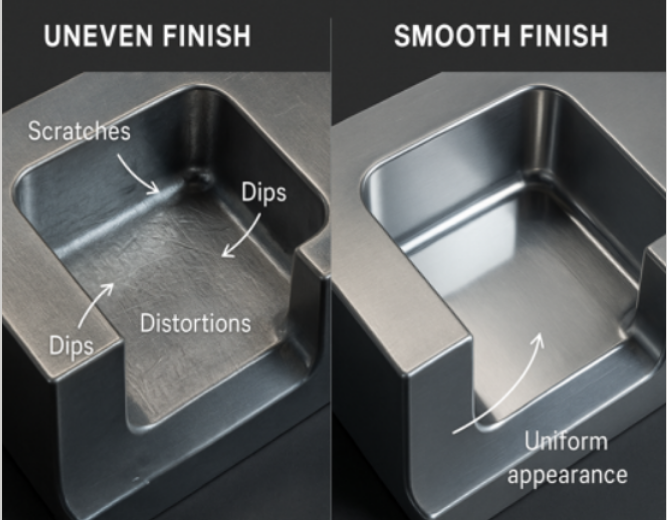

Mould polishing machinery is specialized equipment used in the refinishing and smoothing of surfaces of mould cavities and cores. It removes machining marks, raises gloss on the surface, and can meet even tight tolerance requirements.

Polishing is not all about appearances—it is all about working. The smoother the surface of the mould, the freer the flow of the material; there will be less wear in production, leading to improved part quality and extended mould life.

Why Mould Polishing Matters

- Improves Product Quality: A polished mould produces parts with better surface finish, minimizing post-processing and rejection rates.

- Enhances Mould Life: Rough surfaces cause friction and wear. Polishing ensures a smoother surface that lasts longer under repeated use.

- Reduces Defects: Imperfections like weld lines, burn marks, or flow lines are minimized with a clean, polished cavity.

- Boosts Efficiency: Polished surfaces allow faster material flow, reducing cycle time and improving productivity.

- Easier Ejection: Polished moulds make it easier for parts to be ejected cleanly without sticking or distortion.

Plassteze: The Trusted Name in Mould Polishing Equipment

The toolrooms turn to Plassteze to get reliable and efficient polishing applications and solutions for their moulds. With years of experience in the die and mould industry, Plassteze provides specialized machinery to complete sophisticated polishing jobs.

These polishing machines can be used with different mould materials such as tool steels, aluminum, and copper alloys. Keeping operator comfort and exact surface control in view, the machines ensure perfect polishing every time.

Features of Plassteze Mould Polishing Machines:

- High-speed motors with adjustable RPMs for precision polishing

- Lightweight, ergonomic handpieces for extended usage

- Interchangeable polishing tools (abrasive stones, diamond paste, felt bobs)

- Low vibration systems for comfort and accuracy

- Compact designs suitable for any toolroom or mould repair unit

Common Industries Using Mould Polishing Equipment

- Automotive – For high-gloss parts and fine-detailed moulds

- Plastic Injection Moulding – For multi-cavity precision moulds

- Medical Devices – Where surface hygiene and smoothness are critical

- Packaging – For cosmetic perfection and high-speed production

- Electronics & Appliances – For plastic casings and structural parts

Key Considerations Before Choosing a Mould Polishing Machine

- Type of material to be polished

- Size and complexity of mould

- Required finish grade (mirror finish, satin, etc.)

- Operator experience

- Budget and ROI

Plassteze offers expert consultation to help you pick the right equipment for your specific mould polishing needs.

Conclusion

A mould polishing machine is not just an accessory — it's a necessity for any toolroom aiming for perfection, efficiency, and long-term durability.

From improving surface finish to reducing production defects, polishing is the final step that makes a big difference.

And when precision matters, trust only the best. Plassteze delivers mould polishing solutions that redefine industry standards.

Ready to upgrade your toolroom? Reach out to Plassteze today and experience polishing at its finest.

Frequently Asked Questions (FAQs)

- What is the main purpose of a mould polishing machine?

A mould polishing machine is used to smooth and refine the surface of mould cavities and cores, ensuring high-quality, defect-free finished parts. - Can I use polishing equipment on old or damaged moulds?

Yes. Mould polishing machines are often used in refurbishing operations to restore worn or damaged moulds back to usable condition. - What types of tools can be used with polishing machines?

Common tools include abrasive stones, diamond pastes, carbide burrs, felt bobs, and polishing compounds—depending on the material and finish required. - Does polishing increase the lifespan of a mould?

Absolutely. Polished moulds face less wear and reduce friction during the production cycle, which can significantly extend their operational life. - Why choose Plassteze for mould polishing machines?

Plassteze combines decades of experience with innovation, offering durable, high-performance polishing solutions trusted across multiple industries.