Keep Your Moulds Clean with Cooling Line Descaling Machines

The world of mould and die manufacturing places clean cooling channels as a foremost requirement in scaling efficient production. Cooling lines inside the mould get clogged usually by scale, rust, or mineral deposits, thus hindering the cooling, increasing cycle times, and sometimes causing damage to the mould. Enter a descaling and flushing system-a must-have toolroom solution to keep the moulds working while avoiding huge downtime. And that name most moulding industrialists trust is Plassteze.

What is a Descaling and Flushing System?

A descaling and flushing system is a compact machine designed to clean internal mould cooling channels. It circulates special descaling chemicals at high pressure through the water lines, dissolving scale, rust, and deposits — without needing to dismantle the mould.

These machines are ideal for cleaning:

- Injection moulds

- Die-casting moulds

- Cooling plates

- Heat exchangers

Why Regular Descaling is Important

Clogged cooling channels reduce heat transfer, leading to:

- Overheating of the mould

- Increased cycle times

- Part warpage and defects

- Reduced mould life

- Higher energy consumption

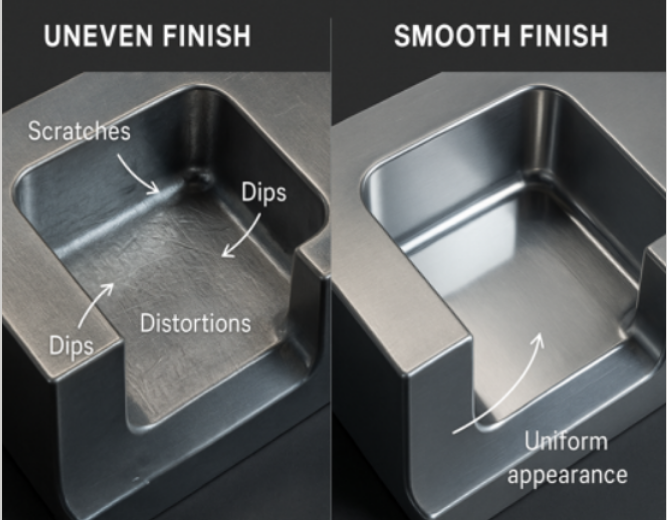

With a reliable mould Cooling Line Descaling Machine, you can maintain smooth production and reduce defects caused by poor cooling.

Benefits of Using Plassteze’s Descaling System

Plassteze offers industry-grade descaling and flushing systems designed specifically for toolrooms. Their machines are durable, easy to operate, and highly efficient.

Key Features:

- Reverse flushing for deep cleaning

- Digital flow and temperature control

- Corrosion-resistant stainless steel body

- Compatible with eco-friendly descaling agents

- Quick setup and mobility

Applications Across Industries

Plassteze’s cooling channel flushing machines are widely used in:

- Automotive moulding – for engine parts, interior trims

- Medical tooling – for precise, defect-free components

- Packaging industry – where high-speed production needs fast cooling

- Electronics – with micro-channels in compact moulds

- Appliances & consumer goods – for consistent mould quality

Any industry using water-cooled moulds can benefit from regular descaling.

When Should You Flush Your Moulds?

It’s recommended to descale:

- After every 20,000–30,000 mould cycles

- Before starting a long production batch

- When cooling flow slows down or uneven heating occurs

- During scheduled toolroom maintenance

Conclusion

A clean mould is a productive mould. Investing in a descaling and flushing system is not just about maintenance — it’s about improving quality, cutting costs, and maximizing your mould’s lifespan.

With Plassteze, you're not just buying a machine — you're choosing peace of mind, trusted performance, and toolroom efficiency.

Ready to upgrade your mould maintenance process? Choose Plassteze.

Frequently Asked Questions (FAQs)

- What does a descaling and flushing system do?

It removes internal buildup of scale, rust, and sludge from cooling lines inside moulds and dies, restoring smooth water flow. - Is it safe to use on all types of moulds?

Yes, Plassteze’s system is designed for steel, aluminum, and most mould materials. It uses non-damaging, eco-safe cleaning agents. - Can I clean the mould without dismantling it?

Absolutely. The system is designed to clean the mould in-place, saving time and effort. - How long does a descaling cycle take?

Typically 30–90 minutes depending on the severity of scaling and size of the mould. - Why choose Plassteze over others?

Plassteze is a trusted leader in die & mould solutions, offering reliable equipment with expert support and long-lasting performance.

Whether you're doing routine cleaning or deep flushing after tool downtime, Plassteze’s system makes the process fast and safe.