- Email us: plassteze@plassteze.com

- Home

- About Us

-

Products

- Mould Polishing Equipment

- World Class Mould Polishing Consumables

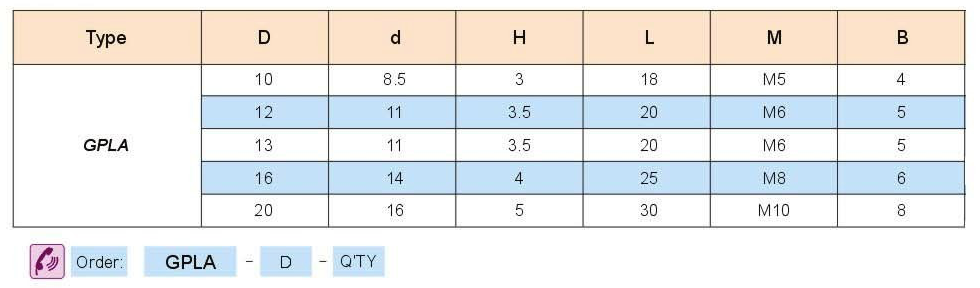

- Standard Mould Parts

- Mould Service Table

- e-CAMGUARD Die-Mould Protection System

- Cooling Line Descaling Machine

- AIRTECT Plastic Leak Detection System

- Ultrasonic Cleaner

- Die Spotting Press

- Trimming Press

- Sinker EDM Machine

- Leak & Flow Test Machine

- Blog

- Contact