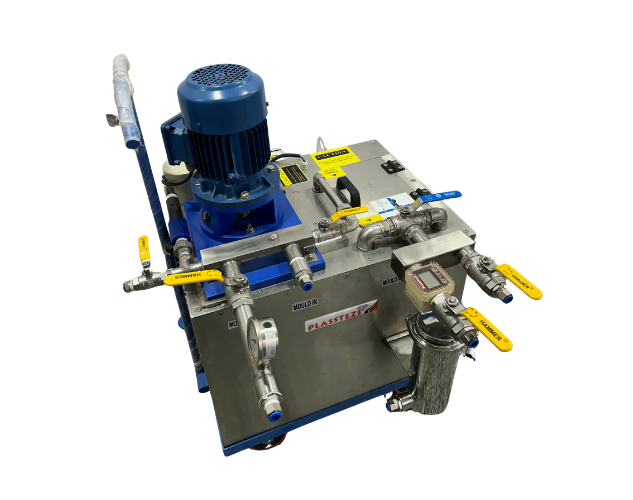

Cooling Line Descaling Machine

The Cooling Line Descaling Machine is equipped with an extremely powerful pump to

flush out stubborn scale, rust, and deposits formed in cooling channels.

Timer-controlled operations make it safe to use and prevent excessive contact of

chemicals with the cooling channels. An auto cut-off heater maintains the optimum

temperature for best results.

During production, the mold pipeline needs to be filled with cooling media such as

water, steam, or heat-conducting oil to control the mold temperature. Since the mold

cooling pipe constantly alternates between hot and cold conditions, scale, carbon

deposits, and rust easily form on its inner walls. Bacteria and algae also multiply

in large quantities, further restricting the pipe diameter and, in some cases,

causing complete blockages.

These issues significantly reduce heat exchange efficiency, leading to unstable

product quality, higher defect rates, and increased production costs.

Our descaling machines helps you save costs by improving the cooling efficiency of

cooling channels in dies and molds, injection molding machines, heat exchangers,

boilers, and central heating/cooling plumbing.